Plasma Cleaners

Tergeo series

Tergeo series tabletop plasma cleaners

1. Intelligent and intuitive design

2. Quantitative plasma measurement technology

3. Immersion and downstream plasma processing modes in one system

4. Recipe and job sequence

5. Pulsed operation

Why choose Tergeo plasma cleaner

- Better plasma uniformity with external electrode design

- Unique plasma sensor technology for quantitative plasma strength measurement

- Advanced process control technology

- Direct immersion mode and downstream plasma processing mode in one system

- Mass flow controller (MFC) regulated gas input instead of manual rotameter or coarse needle valve

- Advanced digital pressure sensor for accurate pressure monitoring

- Fully automatic operation with 20 recipe support

- Intuitive resistive touchscreen user interface

- External RF electrode and quartz chamber can eliminate the metal contamination issue on plasma systems with internal metal electrodes

- High frequency 13.56MHz rf power supply with automatic impedance matching to reduce energetic ion sputtering damage in KHz rf system

Scanning electron microscopy

Plasma Cleaner

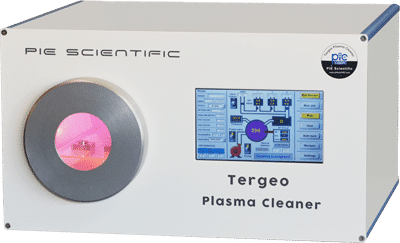

Tergeo

Typical applications:

- Wire bonding, flip chip underfill, device encapsulation and decapsulation

- SEM/TEM sample cleaning for carbonaceous contamination removal and oxide reduction

- Surface treat before biomedical coating and improve hydrophilicity of medical implants

- Optics, glass and substrate cleaning before epoxy bonding

- Photoresist ashing, descum and silicon wafer cleaning

- PDMS, microfluidics, glass slides and lab-on-a-chip

- Improve bonding for metal to metal or composite

- Improve bonding for plastic, polymer and composite materials

Features:

- Cleaning modes: Immersion plasma cleaning for high speed etching and surface modification; remote plasma cleaning for gentle surface contamination removal, such as SEM/TEM sample cleaning; pulsed operation to generate plasma with average rf power less than 0.5watt for extremely delicate samples.

- Operation methods: Automatic recipe execution; automatic job sequence execution; manual operation.

- Plasma sensor: dual plasma strength sensor (patent pending) monitors in-situ plasma source and remote plasma source. Plasma strengths are displayed on the LCD touchscreen in real-time.

- Advanced process control capabilities: pressure sensor, temperature sensor, gas flow rate meters in MFC, dual plasma strength sensors, automatic impedance matching

- Chamber materials: Aluminum flange and thick-wall high purity quartz tube offer enhanced chemical resistance and reduction of alkali impurities (Ca, K, Na) found in pyrex glass.

- Quartz chamber size: inner diameter:110mm; outer diameter: 120mm; depth 280mm

- Sample holder: 2mm thick high purity quartz plate

- RF antenna: External rf electrodes and antenna design reduces metal sputtering issue found in plasma cleaners with internal metal electrodes.

- RF power: 13.56MHz high frequency rf power supply with automatic impedance matching for in-situ plasma source. RF power has two options: 0-75watt and 0-150watt. 13.56MHz rf power generates plasma with much higher density than KHz power supply.

- Gas input: Up to three mass flow controlled gas input (0~100sccm). One additional port for venting and purging. ¼ inch Swagelok compression fitting connectors.

- User interface: 7-inch resistive touchscreen, touch with fingers, no stylus required.

- Recipe and job support: Total 20 customizable recipes. Up to three cleaning steps in job sequence.

Plasma Cleaner

Tergeo-plus

Large chamber tabletop plasma cleaner for R&D, low to mid volume production.

The only difference between Tergeo-plus and Tergeo plasma cleaner is the size of the sample chamber. The inner diameter of the sample chamber has been increased from 110mm in Tergeo to 160mm in Tergeo-plus. The depth of the sample chamber is the same, e.g. 280mm.

Application of Tergeo-plus plasma cleaner is similar as the standard Tergeo plasma cleaner, except that it can accommodate larger samples.

Here are list of typical applications:

- Wire bonding, flip chip underfill, device encapsulation and decapsulation

- Surface treat before biomedical coating and improve hydrophilicity of medical implants

- Optics, glass and substrate cleaning before epoxy bonding

- Photoresist ashing, descum and silicon wafer cleaning

- PDMS, microfluidics, glass slides and lab-on-a-chip

- SEM/TEM sample cleaning for hydrocarbon contamination removal

- Improve bonding for metal to metal or composite

- Improve bonding for plastic, polymer and composite materials

Features:

- Large sample chamber (ID:160mm, L280mm). Enough to accommodate a 4-inch wafer boat and one 6-inch wafer.

- Cleaning modes: Immersion plasma cleaning for high speed etching and surface modification; remote plasma cleaning for gentle surface contamination removal, such as SEM/TEM sample cleaning; pulsed operation to generate plasma with average rf power less than 0.5watt for extremely delicate samples.

- Operation methods: Automatic recipe execution; automatic job sequence execution; manual operation.

- Plasma sensor: dual plasma strength sensor (patent pending) monitors in-situ plasma source and remote plasma source. Plasma strengths are displayed on the LCD touchscreen display in real-time.

- Advanced process control capabilities: pressure sensor, temperature sensor, gas flow rate meters in MFC, dual plasma strength sensors, automatic impedance matching

- Chamber materials: Aluminum flange and thick-wall high purity quartz tube offer enhanced chemical resistance and reduction of alkali impurities (Ca, K, Na) found in pyrex glass.

- Sample holder: 2mm thick high purity quartz plate

- Chamber size: inner diameter:160mm; outer diameter: 170mm; depth 280mm

- RF electrodes: External rf electrodes and antenna design reduces metal sputtering compared with internal metal electrodes in other plasma cleaners.

- RF power: 13.56MHz high frequency rf power supply with automatic impedance matching for in-situ plasma source. RF power has two options: 0-75watt and 0-150watt. 13.56MHz rf power generates plasma with much higher density than KHz power supply.

- Gas input: Up to three MFC controlled gas input (0~100sccm). One additional port for venting and purging. ¼ inch Swagelok compression fitting connectors.

- User interface: 7-inch resistive touchscreen, touch with fingers, no stylus required.

- Recipe and job support: Total 20 customizable recipes. Up to three cleaning steps in job sequence.

Plasma Cleaner

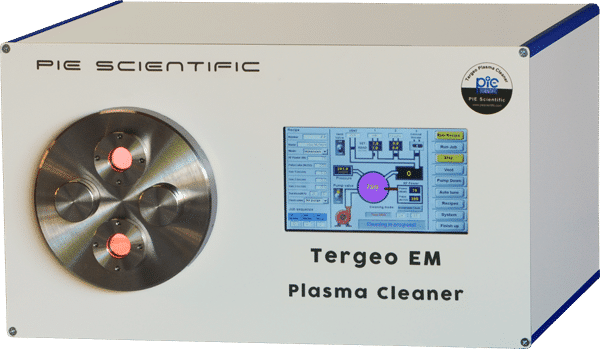

Tergeo-EM

Tabletop plasma cleaner for TEM and SEM labs

Customers in many prestigous research institutes around the world have purchased our Tergeo-EM plasma system for cryo-EM, in-situ TEM, materials research and other type of high resolution electron microscopy applications. Tergeo-EM plasma cleaning system and TEM holder vacuum storage system have been well received by TEM & SEM users in Caltech, UC-Berkeley, UIUC, NIH, Harvard, EAG Laboratories, French National Centre for Scientific Research (CNRS), Max-Planck-Institut in Germany, University of LEES in UK, Tsinghua University in China, National University in Singapore, and so on. Many of our Tergeo-EM customers are former users plasma cleaners and they all think our Tergeo-EM plasma system and vacuum storage systme are much easier to use and are very versatile.

Tergeo-EM plasma cleaner can be used to remove hydrocarbon contaminations on TEM and SEM samples. It can accept two TEM specimen holders at the same time. The front adapter can be easily replaced to support more than two different types of TEMS. User can also directly load SEM and TEM samples into the plasma chamber. The chamber is bigger enough to holder two 4" wafers. Tergeo-EM has been widely used to make TEM grid hydrophilic for cryo-EM applications. It can also activate the surface of the liquid cell in-situ chip. Unique dual plasma source design and pulsed mode operation enable wide range of applications including high speed removal of STEM carbon burn mark, clean carbon deposition on column apertures and gantle surface activation of ultra-thin holey carbon grids and graphene grids.

Applications:

- Removing hydrocarbon contamination on TEM and SEM samples before imaging.

- Removing carbon deposition after STEM imaging.

- Making TEM grid hydrophilic for cryo-EM applications. Unique gentle downstream mode and pulsed plasma can handle ultra-thin carbon and graphene grids without damaging the fragile grids

- Removing organic contamination and activate in-situ TEM and SEM chip surface. Making liquid cell surface hydrophilic.

- Support Thermo-fisher (FEI), JEOL and Hitachi specimen holder, cryo-em autoloader cassette, SEM stud and regular TEM grids on any holders

Features:

Tergeo-EM plasma cleaner is the only TEM/SEM plasma cleaner that has integrated both immersion mode plasma cleaning (samples are immersed in plasma) and downstream mode plasma cleaning (samples are placed outside the plasma) in one system. Downstream plasma clean totally eliminate the ion sputtering of samples. In addition, unique pulsed mode operation can generate extremely short plasma pulses to further reduced the plasma intensity for delicate samples. Patented plasma sensor technology monitors the plasma strength in real time. It helps user to set up right cleaning recipe for different types of samples.

Tergeo-EM plasma cleaner can meet all the requirements from high speed cleaning for heavily contaminated apertures and electrodes in electron optics column to gentle cleaning for samples like graphene, carbon nanotube, DLC (diamond-like carbon), carbon fiber or TEM samples on holey carbon grid. Tergeo-EM plasma cleaner is equipped with an oil free dry pump safe for oxygen service. Usually air or 80%Ar+20%O2 gas mixture can be used for SEM/TEM sample cleaning application. Two to three mass flow controlled gas delivery ports are available to mix multiple process gases.

Plasma Cleaner

Tergeo-EM

Tabletop plasma cleaner for TEM and SEM labs

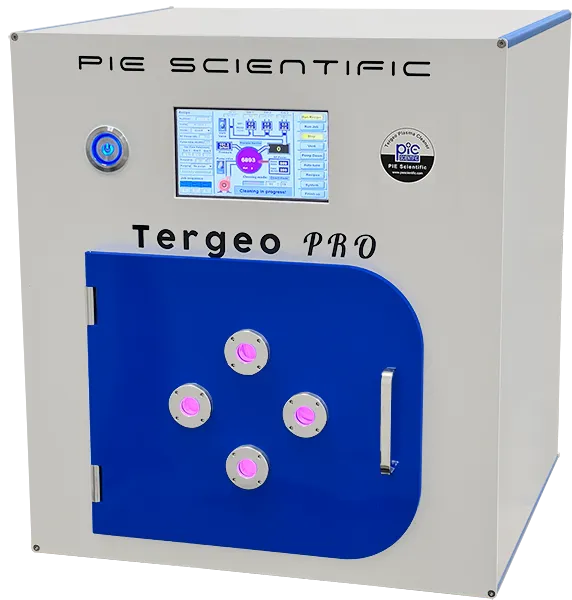

Tergeo-Pro plasma system future increases the chamber diameter to 9″ (230mm) in diameter. The depth of the chamber increases to 13.4″ (430mm). Tergeo-Pro plasma system is bigger enough to hold an 8″ wafer. It's also bigger enough for one or two 25/50 slot 6″ or 4″ quartz wafer boats.

Tergeo-Pro plasma system can have 150-Watt, 300-Watt, or 500-Watt rf power. RF power can be adjusted at 1-watt intervals. The frequency of the rf power is 13.56MHz, which offers much higher plasma generation efficiency than the KHz rf plasma systems.

Tergeo plasma systems not only adjust the rf power wattage, but they can also create continuous or pulsed plasma. The pulse ratio can be adjusted from 100% to less than 1%. Quartz chamber wall construction enables external capacitively coupled rf electrode design, which generates more uniform plasma across the whole chamber.

Contact us for more information on this product

Would you like an estimation ?

Additional information?

We will reply to you within 24 hours