Mechanical profilometer with the best quality / price ratio

P7

1. Height of steps from a few nanometers to a millimeter

2. Production and R&D

3. 150mm plate

4. Manual 360 ° rotation

5. 2D and 3D measurements

6. Roughness, bow and constraints

The P-7 builds on the success of the market-leading P-17 table stylus profiling system. It integrates the superior measurement performance of P-17 technology into a platform offering an excellent price / functionality ratio for a table-top mechanical profilometer. The P-7 offers the ability to measure the height of steps from a few nanometers to a millimeter, for production and research and development environments.

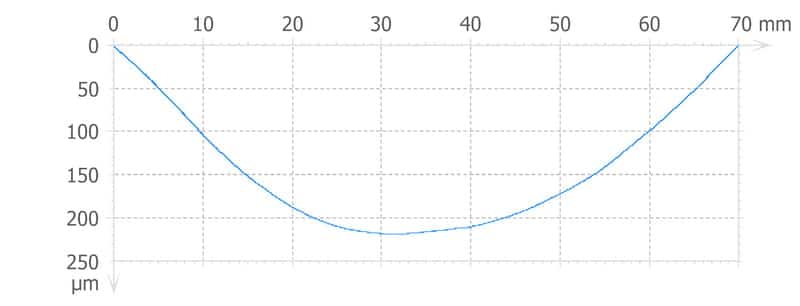

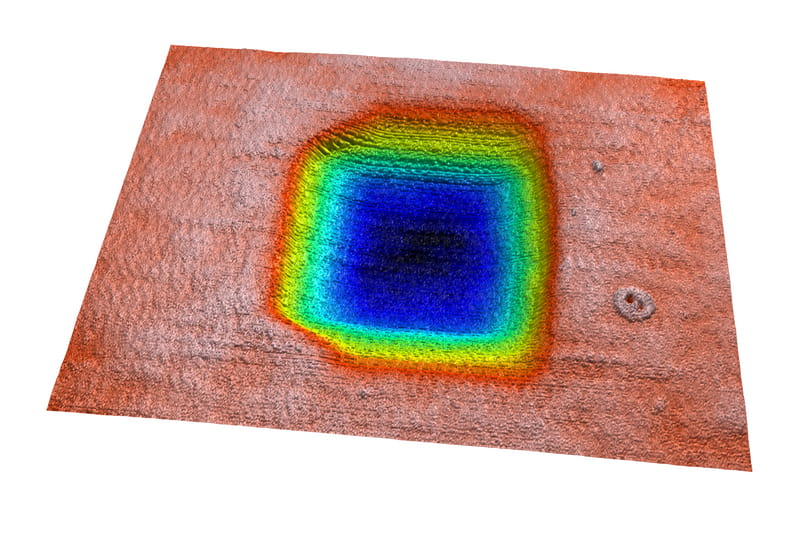

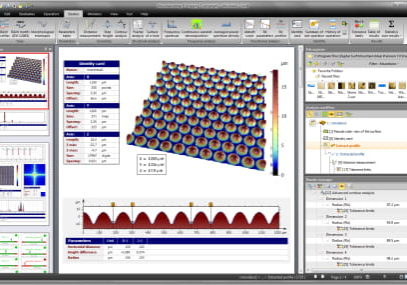

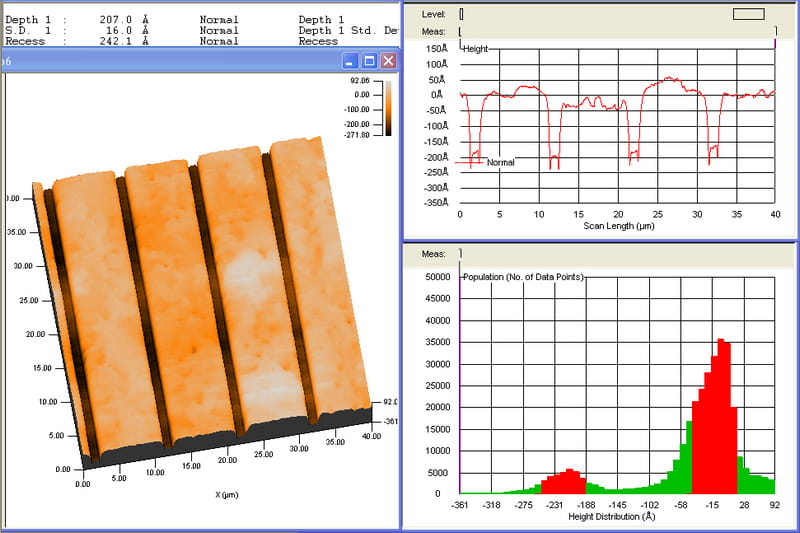

The system supports 2D and 3D measurements of pitch, roughness, bows and constraints for scans of up to 150 mm seamless.

Mechanical profilometry applications

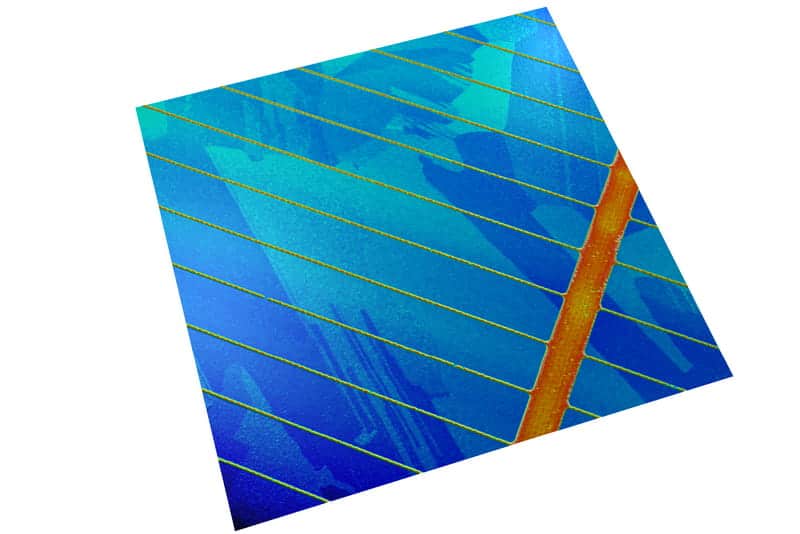

- Step height: 2D and 3D step height

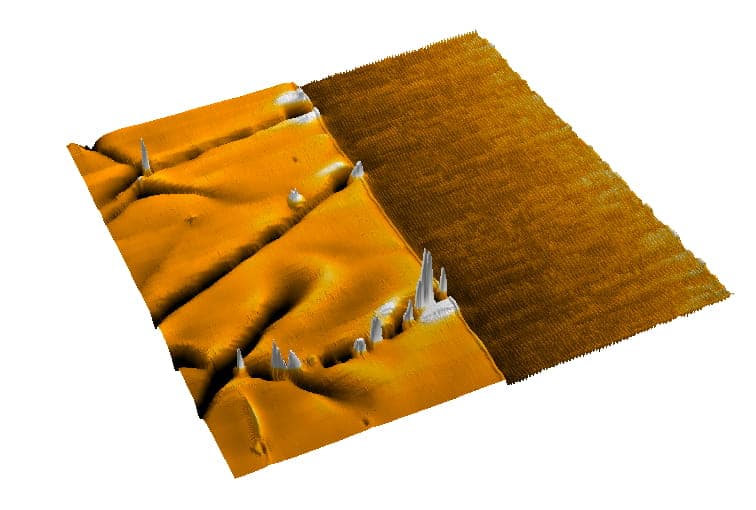

- Texture: 2D and 3D roughness and waviness

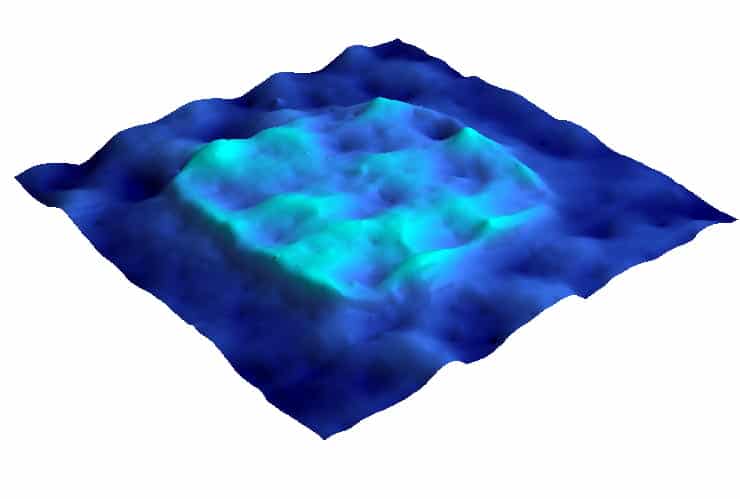

- Shape: 2D and 3D arc and shape

- Stress: 2D and 3D thin film stress

- Examination of defects: topography of the surface of 2D and 3D defects

- industries

- Universities, research laboratories and institutes

- Semiconductor and compound semiconductor

- LED: light emitting diodes

- Solar

- MEMS: micro-electro-mechanical systems

- Data storage

- automobile

- Medical equipement

- Universities, research laboratories and institutes

More info on applications

- Height of steps

- Texture: roughness and waviness

- Shape: bow and shape

- 2D and 3D thin layer stress

Profilometry at the best quality / price

ADVANTAGES

- Production and R&D

- 150mm plate

- Rotation is manual over 360 °

- 2D and 3D measurements

- Roughness, bow and constraints

- Step height: Nanometers up to 1000 µm

- Low strength with constant strength control: 0.03 to 50 mg

- Scan the full diameter of the sample without sewing

- Video: High resolution 5MP color camera

- Arc correction: removes errors due to stylus arc movement

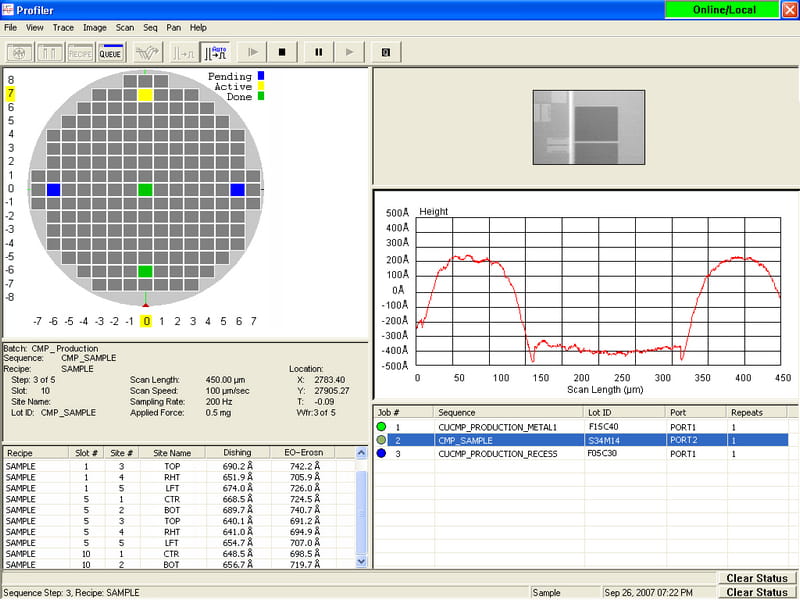

- Software: easy to use software interface

- Production capacity: Fully automated with sequencing, pattern recognition and SECS / GEM

Options

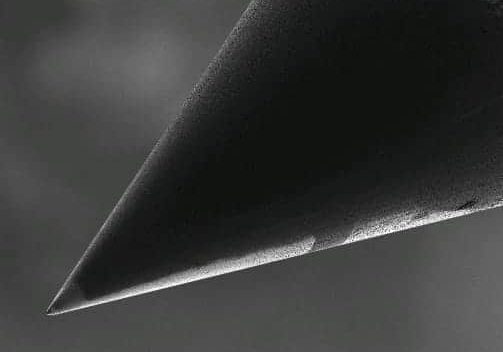

Stylus options

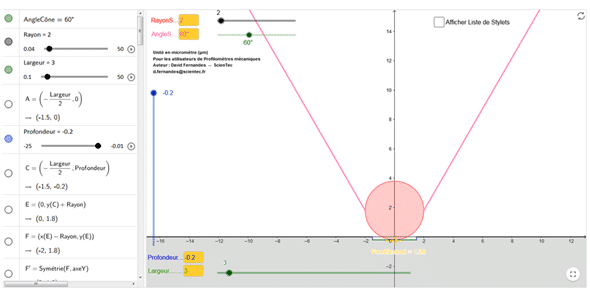

The P-7 offers a variety of styli available to support the measurement of step height, steps with a high aspect ratio, roughness, sample curvature and stresses. The tip radius is between 100 nm and 50 µm and determines the lateral resolution of the measurement. The included angle ranges from 20 to 100 degrees, which specifies the maximum aspect ratio of the feature being measured. All styli are made from diamond to reduce wear and increase the lifespan of the stylus.

Sample plate

The P-7 has a range of chucks available to meet application needs. The standard is a universal vacuum chuck with precision positioning pins for samples from 50 to 150 mm. The universal mandrel supports arc and strain measurements with 3-point locators to support the sample in a neutral position. Additional options for solar samples and 200mm universal chucks are available.

Insulation tables

The P-7 offers both table and stand-alone insulation options. The Granite Isolator ™ series offers table systems combining granite with high quality silicone gel to provide passive insulation. The Onyz series table insulation systems use pneumatic isolators to provide passive insulation. The TMC 63-500 series isolation table is a stand-alone steel frame table that uses pneumatic isolators to provide passive isolation.

Step height

The P-7 uses NIST traceable step height standards, thin and thick, proposed by VLSI standards. The standards include an oxide step on a silicon matrix mounted on a quartz block or an engraved quartz step with a chrome coating. A step height range of 8 nm to 250 µm is available.

Apex analysis software

Apex analysis software enhances the standard data analysis capability of the P-7 with an extensive suite of leveling, filtering, stage height, roughness and surface topography analysis techniques. Apex supports ISO roughness calculation methods, as well as local standards such as ASME. Apex can also serve as a reporting platform with the ability to add text, annotations and pass / fail criteria. Apex is available in eight languages.

Offline analysis software

The P-7 offline software has the same data analysis and recipe creation capabilities as the tool. This allows the user to create recipes and analyze data without using precious time.

Pattern recognition uses pre-taught patterns to automatically align the sample. This allows fully automated measurements for increased measurement stability by reducing the impact of operator errors. Pattern recognition, combined with advanced calibrations, reduces positioning errors and allows transparent transfer of recipes between systems.

SECS / GEM and HSMS

SECS / GEM and HSMS communications support factory automation systems and allow remote control of the P-7. The measurement results are automatically reported to the host SPC systems, as well as the alarms and the main calibration / configuration data. The P-7 complies with SEMI E4, E5, E30 and E37 standards.

Contact us for more information on this product

Would you like an estimation ?

Additional information?

We will reply to you within 24 hours