Mechanical profilometers

Mechanical profilometry is a surface profile measurement technique with contact by scanning a stylus (fine diamond tip) on the sample. The measured profiles allow the analysis of shape, surface states (roughness, undulation, texturing), to survey in XYZ (3D surface relief), to quantify steps and channels, to characterize a surface constraint (2D stress / 3D). Accurate and repeatable at a few Z Angstroms and can accommodate large samples up to 500x500mm. Discover our solutions with the ranges of KLA Tencor and Toho Technology.

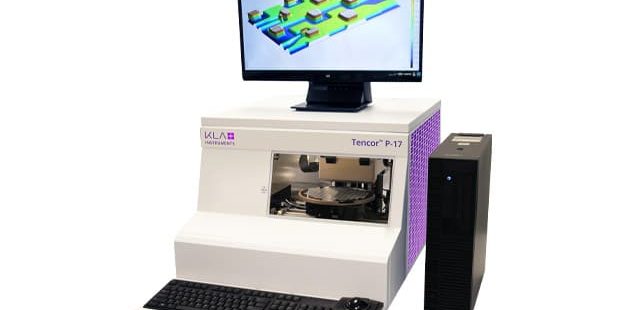

P-17 is the best P series profilometer designed by KLA, a combination of decades of know-how specially adapted to the demands of Industry. The most efficient and effective profilometer, the P-17 has a number of unique features that make it unbeatable in the market for high resolution profilometers for R&D and Industry. The P17 is a fully motorized and automated version.

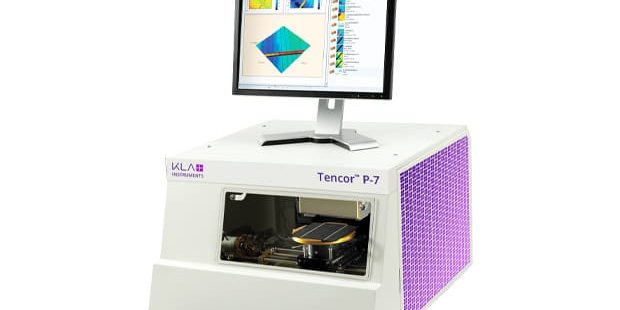

A compact profilometer, it is the light version of the P17, offering the best of KLA technology at a low cost and meeting the majority of surface metrology needs. It has a 150mm plate, motorized in XY. Rotation is manual over 360 °. The P-7 is a metrology tool particularly appreciated in Quality Control for Research and Industry.

The KLA D series includes profilometers dedicated to R&D. The D600 profilometer enables 2D and 3D profile measurement and analysis. It is equipped with a 200mm stage with XY movement motorization, with manual 360 ° rotation and a central suction. As standard, it already has a double optical detector allowing a vertical measurement range of 0-1200µm with sub-nanometric precision and a low adjustable pressing force (0.03 to 15 mg).

The KLA D series includes profilometers dedicated to R&D. The D500 profilometer enables 2D profile measurement and analysis. It is equipped with a 150mm plate with XY displacement and manual rotation. As standard, it already has a double optical detector allowing a vertical measurement range of 0-1200µm with sub-nanometric precision and a low adjustable pressing force (0.03 to 15 mg). Very appreciated for the deposit / etching or structure measurement.

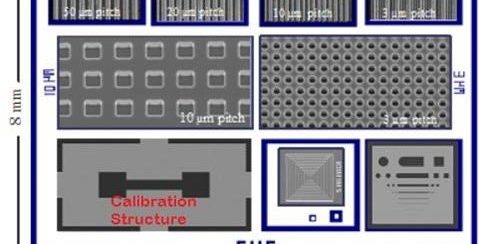

This versatile calibration standard is designed for the calibration of AFM, SEM, optical and mechanical profilers. Features include step heights, lines, grids, magnification box, and measurement structures of different tones Features are etched in SiO2 and Si and are optionally available with a metallic coating for improved reflectivity and loads reduced static.